Diving into the Future: 5 Astonishing 3D Printing Innovations that Redefine Reality

The future is here and it's more tangible than ever. Thanks to the astounding advancements in 3D printing technology, the line between reality and imagination is quickly blurring. This technology, also known as additive manufacturing, has grown leaps and bounds since its inception, revolutionizing various sectors from healthcare to construction, fashion to food, and so much more. In this deep dive, we will explore 18 astonishing 3D printing innovations that redefine reality, offering a glimpse into a future where 3D printing could become as commonplace as smartphones are today.

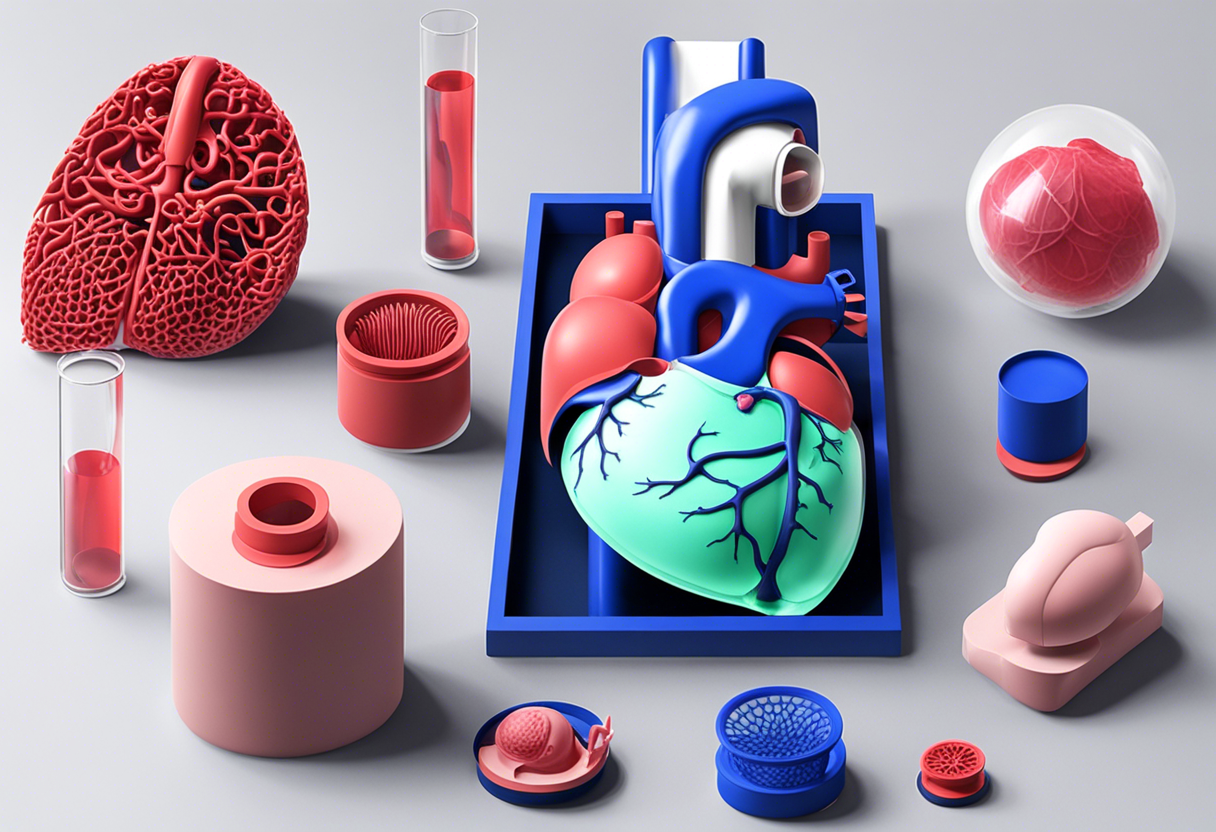

3D Printed Organs

The world of medicine has been particularly revolutionized by 3D printing. Scientists are now able to create 3D printed organs, a breakthrough that could potentially save countless lives. By using a patient's own cells, researchers can minimize the risk of organ rejection. Although still in its experimental stages, this innovation holds immense potential for the future of organ transplantation.

Prosthetics

3D printing has also made a significant impact in the field of prosthetics. Customized prosthetic limbs, tailored to the individual's specific needs, can now be created quickly and inexpensively. This has made prosthetics more accessible to people in developing countries and those who cannot afford traditionally manufactured prosthetics.

Automotive Industry

The automotive industry has also embraced 3D printing. Car manufacturers use this technology to create prototypes, parts, and even entire vehicles. The ability to rapidly prototype designs has significantly reduced the time and cost of the development process.

Construction and Architecture

3D printing is revolutionizing the construction and architecture industry. Companies are now able to print entire houses, buildings, and architectural models, reducing construction time and waste. This technology also enables the creation of complex designs that were previously impossible or extremely expensive to build.

Aerospace

The aerospace industry has been quick to adopt 3D printing. NASA, for example, uses this technology to manufacture parts for spacecraft. The ability to print lightweight, durable parts on-demand has the potential to significantly reduce the cost of space exploration.